Product Overview

Moldflow® simulation software lets you troubleshoot problems with plastic injection and compression molding. Advanced tools and a simplified user interface help you address manufacturing challenges, such as part warpage, cooling channel efficiency, and cycle time reduction.

Specifications

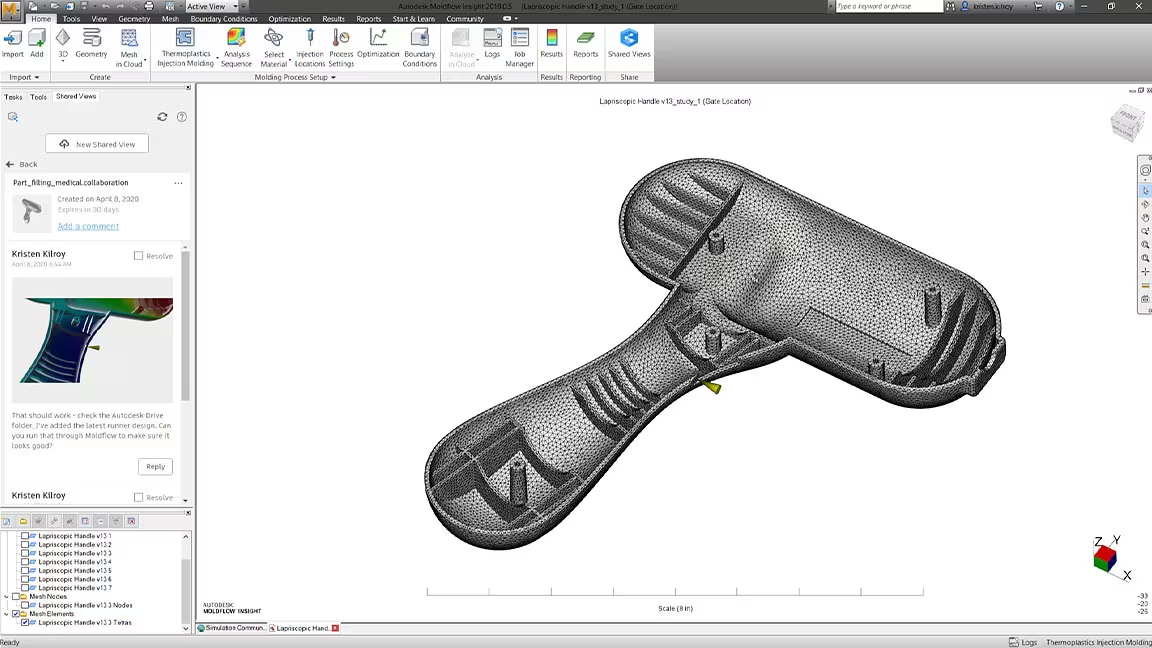

Moldflow® software helps reduce manufacturing defects through plastic injection molding simulation. Access tools for injection mold design, plastic part design, and mold processing.

Runner balancing

Runner balance analysis guides users in sizing multi-cavity runners for even pressure and fill time.

Mold cooling circuits

Automate cooling channel creation with a wizard, import from CAD curves, or manually draw circuits.

Defect visualization

Analyze part warpage and evaluate potential design flaws to improve part quality.

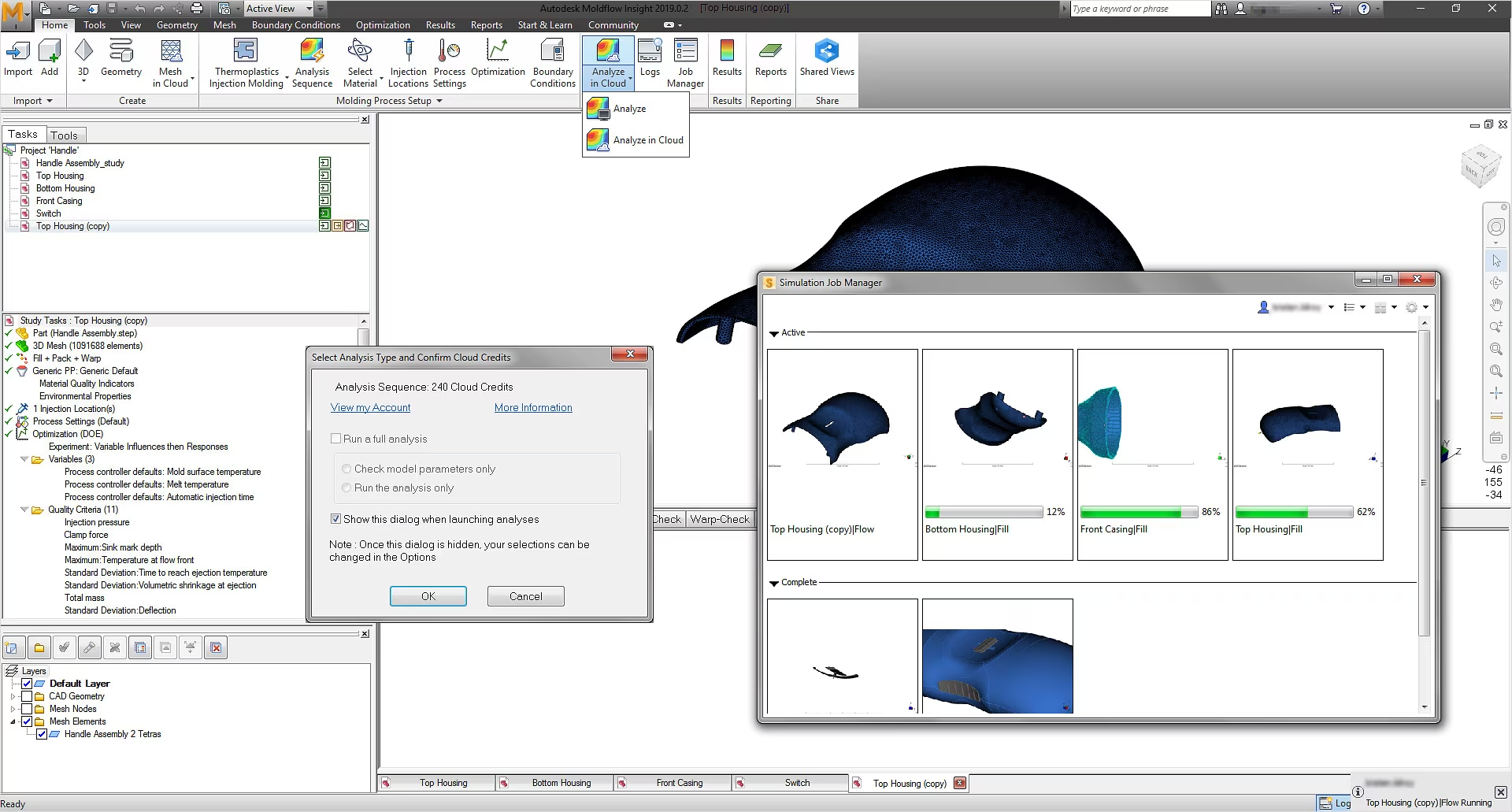

Flexible solving

Use the Simulation Compute Manager (SCM) to solve analyses locally, on a server, or on the cloud.

Chemical Foam Molding

Simulate foaming of thermoplastic and thermoset materials (including polyurethane).

Control valve gate opening/closing

Include controlled and sequential valve gates within simulations, along with hot runner layouts.

Predict shrinkage and warpage

Visualize part quality concerns to identify causes of warpage and apply shrink compensation factors.

Part and process optimization

Use automated design of experiments and parametric analysis to locate the best process and design.

Total coolant flow history

Run a coolant flow analysis to review coolant properties as it flows from the pump to the mold.

Database of 10,000+ materials

Built-in database with information on thousands of tested thermoplastic and thermoset materials.

Mold and insert material assignment

Pre-loaded materials increase accuracy with assigning part and mold insert materials and mold block materials.

Orthotropic part inserts

Simulate continuous fiber inserts made from composite materials or wood, and analyze any overmolded part defects.

Mold cooling

Create or import advanced cooling layouts, such as conformal cooling, and analyze transient heat calculations.

Induction mold heating

Simulate electromagnetic induction heating of mold components.

Core shift prediction

Simulate one-directional core deflection on parts with inserts.